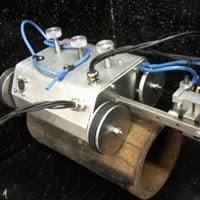

[vc_row][vc_column css=”.vc_custom_1485861403759{margin-top: 25px !important;}”][vc_column_text]The “JD7” pressurised pipe inspection and leak detection system allows all pipework, over 3” diameter, to be examined for condition and leaks whilst operating the network at full pressure. Introduced through existing hydrants and valves it creates no disruption for consumers. Similar to SAHARA Pipeline Inspection System:

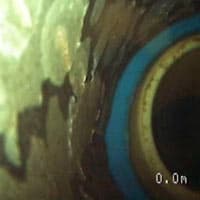

The JD7 is designed for live inspection of large diameter water mains, the Pipeline Inspection System is one of the most accurate tools available for detecting leaks, pockets of trapped gas, and structural defects in complex networks of large diameter water mains.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]

Download Lowflo JD7 Brochure[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]This advanced technology leads to a range of benefits including:

- Elimination of excavation costs

- Pinpoint leaks in all pipe materials

- Underground network management

- Assess pipe structural integrity

- Environmental impact through non- excavation

- Identify leaks and resulting unaccounted for water

- Monitor general pipe condition through leakage

- Prove pipe integrity at critical network crossings (e.g. road and rail)

[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column]

[/vc_column][/vc_row]